Validation - Friction Stir Welding

💰 Price: 55 USD

Reference: X.K Zhu, Y.J Chao. Numerical simulation of transient temperature and residual stresses in friction stir welding of 304L stainless steel

https://www.sciencedirect.com/science/article/abs/pii/S0924013603010288

---

Each plate has 304.8mm in length, 101.6mm in width and 3.18mm in thickness. The pin tool has a shoulder diameter of 19.05mm, and a pin diameter of 6.35mm.

The pin tool starts at 6.4mm away from the edge, and stops after translation of 279.4mm along the weld line

Fig. 1. Geometry configuration of friction stir welding

The tool translated with a velocity of 1.693mm/s; and the total welding time is 165s for each weld.

Fig. 2. Location of thermocouples (300 rpm tool rotational speed)

Material properties are temperature-dependent:

Fig. 3. Variation of material properties with temperature of 304L stainless steel (a) thermal properties, (b) mechanical properties

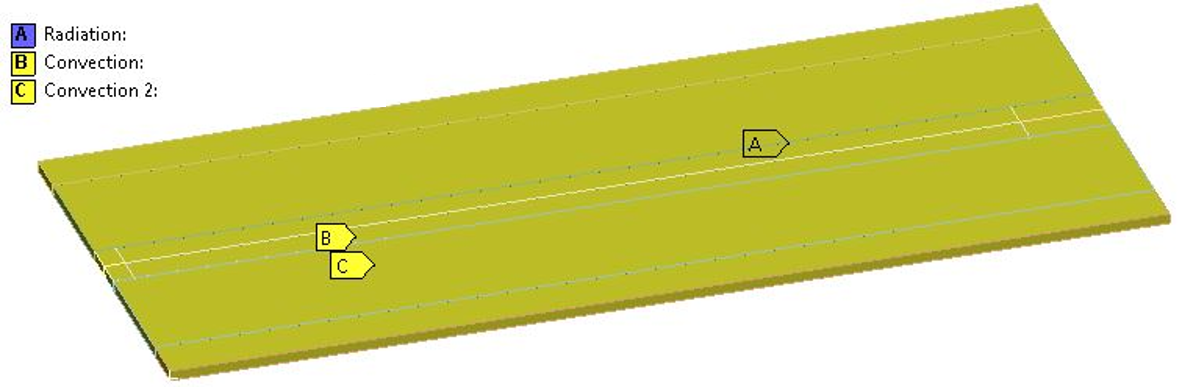

Boundary conditions: Convection with Coefficient = 10W/m2, and Radiation with eps = 0.17

Fig. 4. Convection and Radiation conditions

Results:

Temperature distribution:

Fig. 5. Simulated temperature contour

Variation of transient temperature at locations of the thermocouples for rotational speed of 300 rpm

Fig. 6. On top surface

Fig. 7. On bottom Surface