Friction Stir Welding using ANSYS Fluent

💰 300 USD

Reference: Numerical Simulation of Three-Dimensional Heat Transfer and Plastic Flow During Friction Stir Welding

Authors: R. NANDAN, G.G. ROY, and T. DEBROY

-------------------------

Three-dimensional visco-plastic flow of metals and the temperature fields in friction stir welding have been modeled.

Friction stir welding (FSW) is a solid-state welding process in which the welding is completed without melting of the base metal.

Geometry and Meshing

Workpiece length = 254mm and workpiece width = 204mm with thickness = 12.7mm

Fig 1 - Meshing

The viscosity was calculated based on the flow stress and strain rate

Fig 2 - Viscosity function

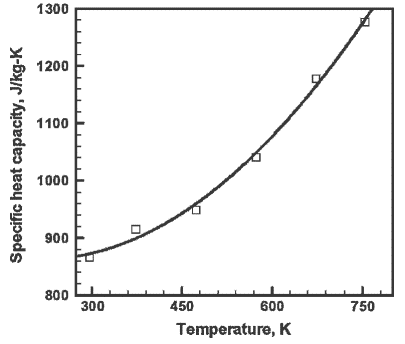

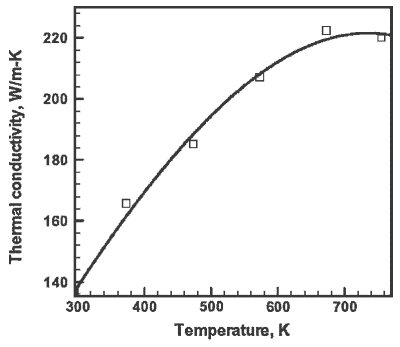

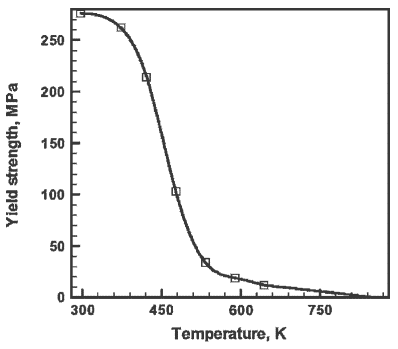

Temperature-dependent material properties

Fig 3 - Material properties

Heat source at Pin' and Shoulder' surface were calculated by function

Fig 4 - Heat source function

Consider a case with Rotation speed equal 344RPM and welding speed equal 1.59mm/s

Results

Temperature distribution

Fig 5 - Temperature distribution

Viscosity distribution

Fig 6 - Viscosity distribution

Fig 7 - Velocity at Pin and Shoulder surface

Fig 8 - Wall heat flux at Pin and Shoulder surface

Temperature profile at point on top surface and 8mm from center line

Fig 9 - Temperature at measure point