WAAM - Thermal Analysis

💰 Price: 65 USD

Reference: https://popups.uliege.be/esaform21/index.php?id=4095

---

Wire arc additive manufacturing process (WAAM) is an innovative technology that offers freedom in terms of designing functional parts, due to its ability to manufacture large and complex workpieces with a high rate of deposition. This technology is a metal AM process using an electric arc heat source.

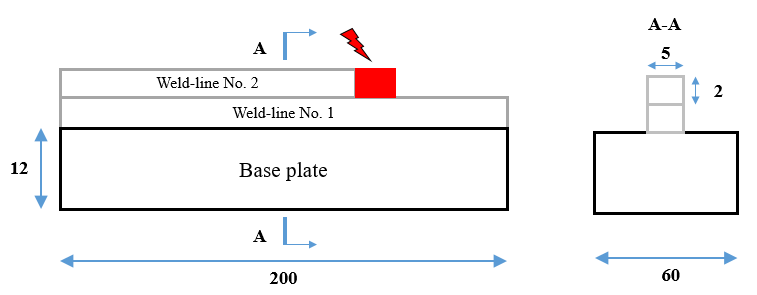

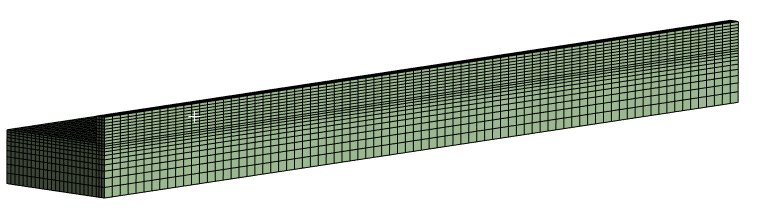

The dimensions of the base plate are 200x60x12 mm3.The wall is built in the middle of the base plate and in the direction of its length. The geometry of these weld-lines is modeled by a rectangular section

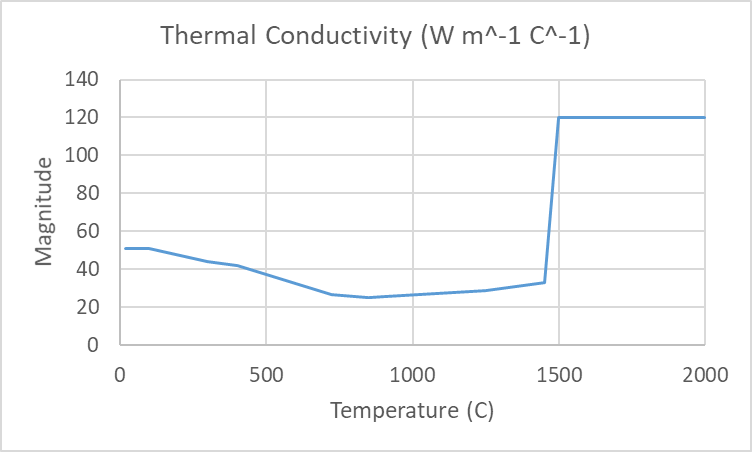

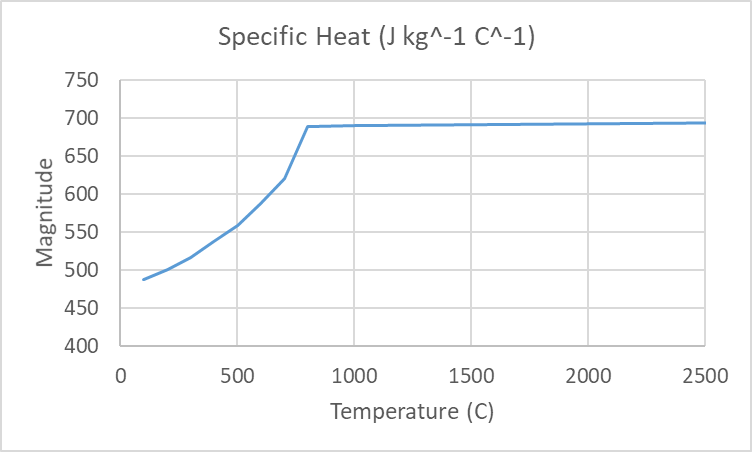

The base plate is made of S355AR-JR steel: Thermal Conductivity and Specific Heat

The numerical model is a transient FE analysis. The heat source is mobile in the x-axis direction and the workpiece remains fixed.

- Along the x-direction, three elements were used to cover the length of the melt pool. The total number of elements along the direction of the deposit is equal to 80 elements with the size of 2.5 mm length.

- Along the y-direction, six elements were used to describe the melt pool with the size of 0.833 mm.

- Along the z-direction, three elements were used to describe the temperature variation with the size of 0.666 mm.

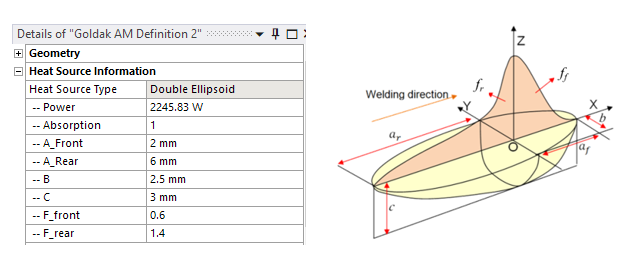

The Goldak model is used:

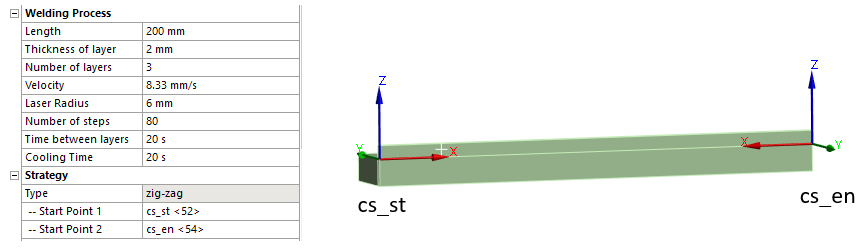

2 Local Coordinate System used to define the Start and End points of the welding process:

Results:

Temperature distribution over model:

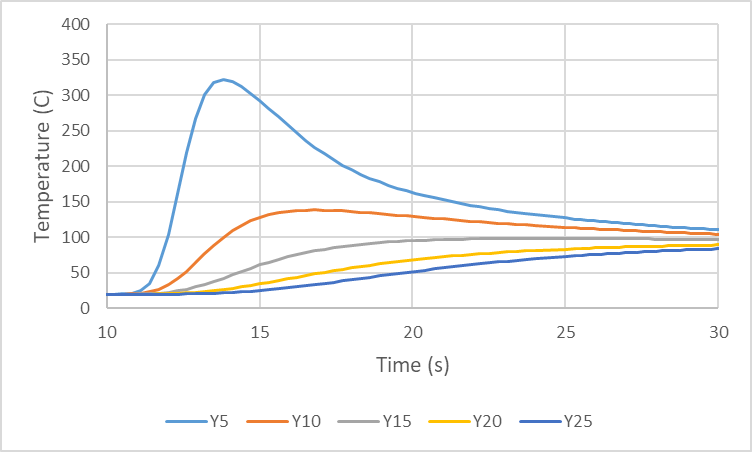

Transient thermal cycles at five points located on a cross section (x=100; z=0):

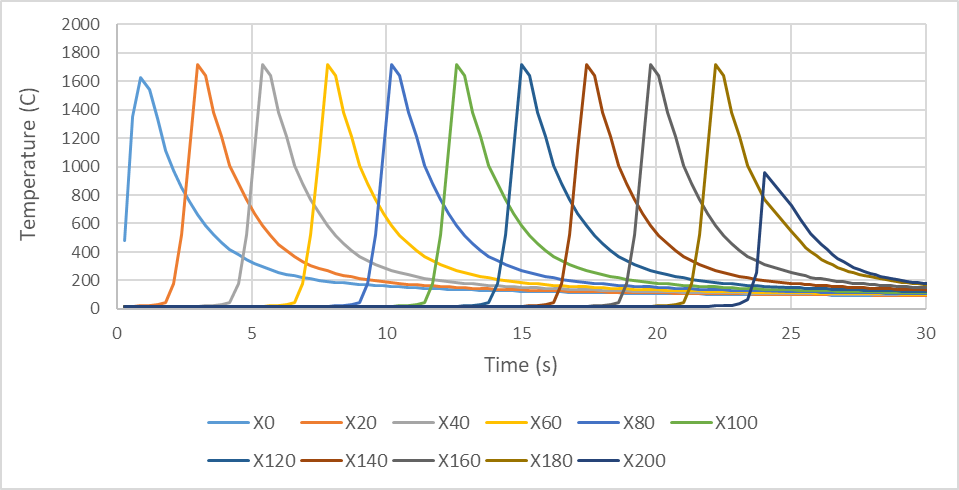

The temperature cycles of eleven points located along the weld-axis (y=0; z=0):