WAAM - Stress analysis

💰 Price: 95 USD

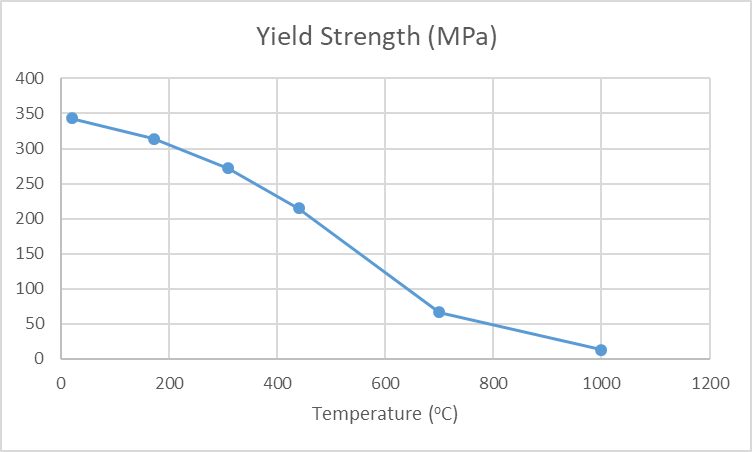

The yield stress is the key mechanical property in welding simulation.

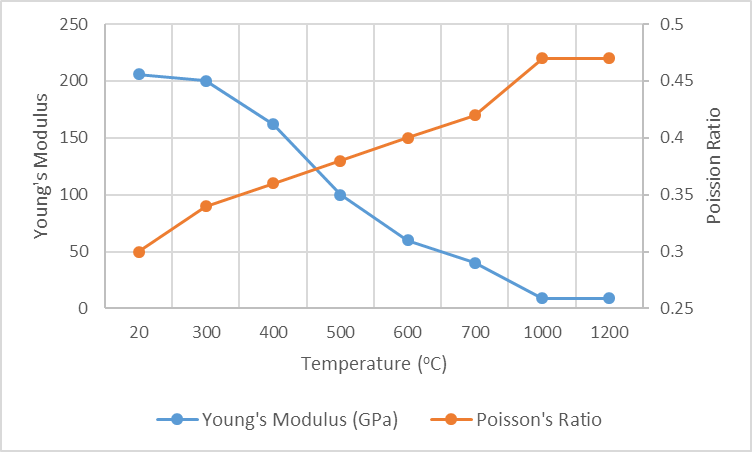

It has a significant effect on the residual stresses and distortions. Thus, accurate temperature dependent yield stresses must be used for the model, temperature-dependent yield stresses are used. Temperature-dependent Young’s modulus and thermal expansion coefficient values were also utilised in the mechanical model.

To avoid difficulties in convergence, a cut-off temperature of 1000°C was used in the material model. Young’s modulus and the yield stress of the material remain at the same value for temperatures above the cut off temperature.

The detailed temperature-dependent mechanical properties of S355:

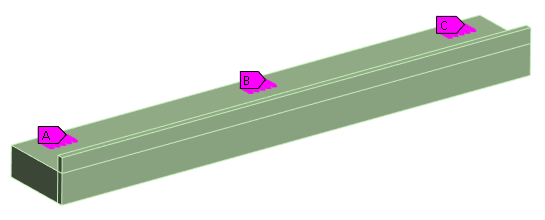

To accurately simulate the clamping systems used in the WAAM process, a backing plate was modelled with a Compression Only condition between the bottom surface of the base plate. It prevented the points on the base plate moving along the –z direction but not against the movement along the +z direction.

In the model, the clamps were used on the four corners and the mid length of the base plate. These were modelled in this study by fixing the movements of the nodes which are demonstrated as the red dots:

The temperature results from the thermal analysis were used as initial conditions for the stress analysis.

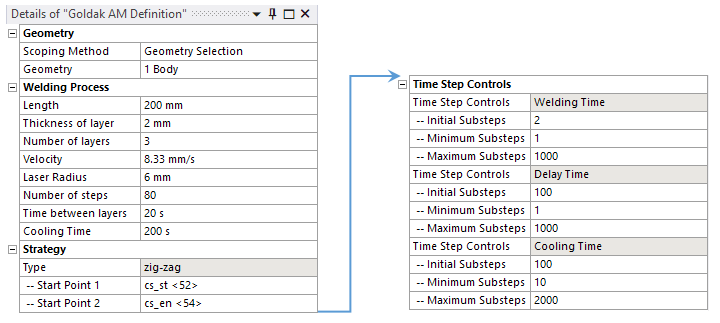

The settings for the welding process are the same as in the thermal analysis.

Results:

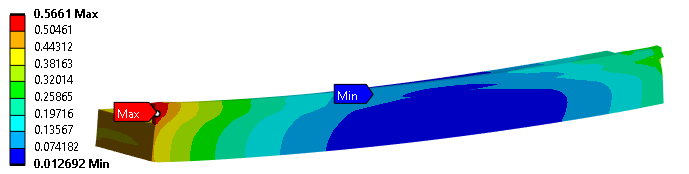

1. Total Deformation

Distortion:

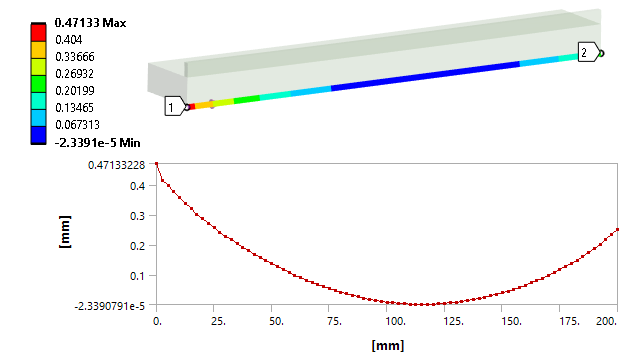

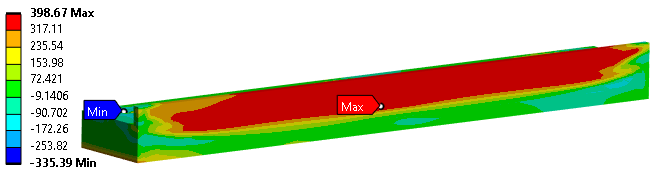

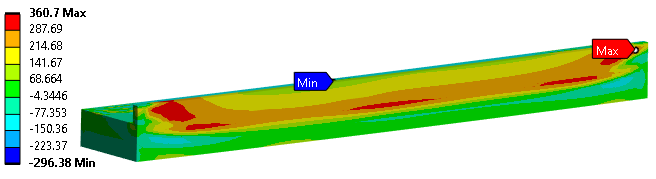

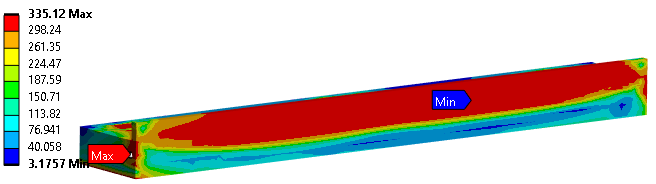

2. Longitudinal stress

Before unclamping:

After unclamping:

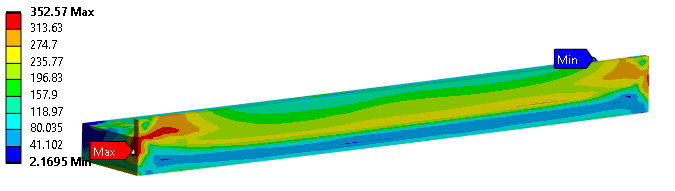

3. Equivalent Stress (von-Mise)

Before unclamping:

After unclamping: