Friction Stir Welding: Part 1/3 - Thermal Analysis |

|

|||||

Reference article: Numerical simulation of transient temperature and residual stresses in friction stir welding of 304L stainless steel

Authors: X.K Zhu, Y.J Chao

https://www.sciencedirect.com/science/article/abs/pii/S0924013603010288

-----

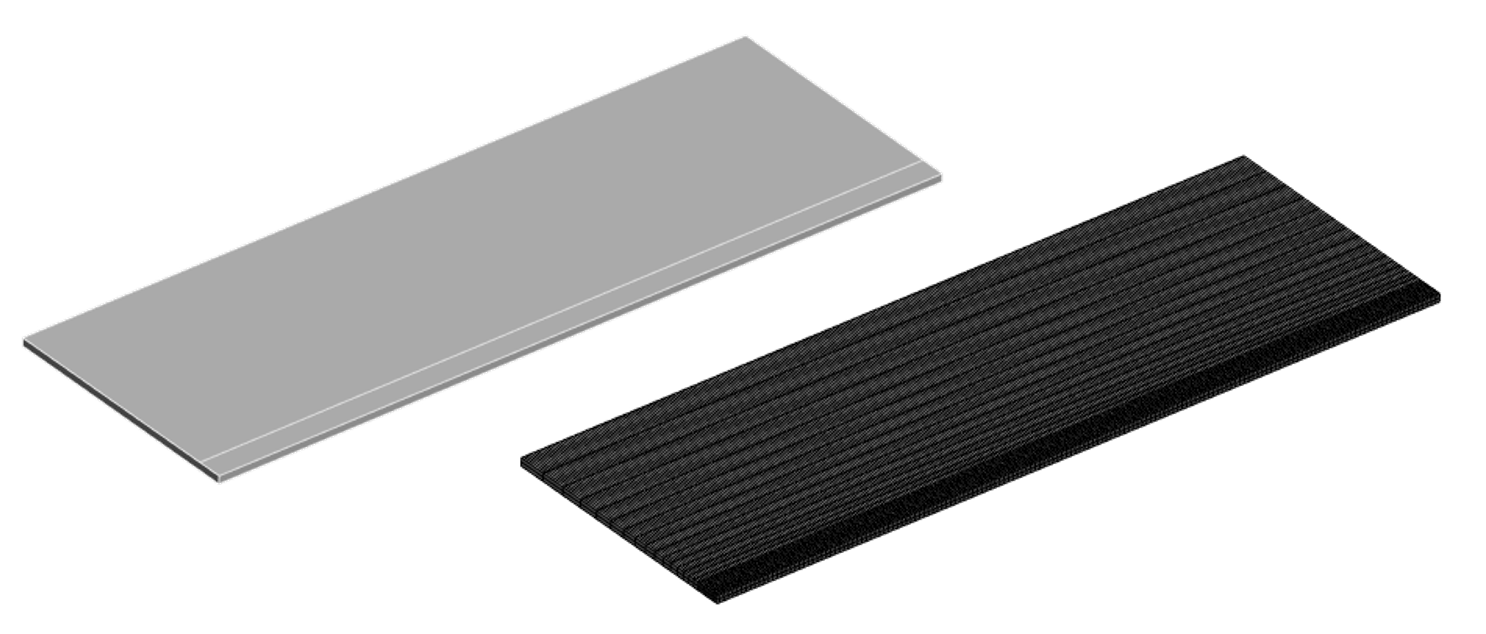

In the numerical simulation of the FSW for 304L stainless steel, it is assumed that the two plates are welded symmetrically during welding and after welding. The weld line is the symmetric line, and thus only half of the welded plate is modeled.

Each plate has 304.8 mm in length, 101.6 mm in width and 3.18 mm in thickness

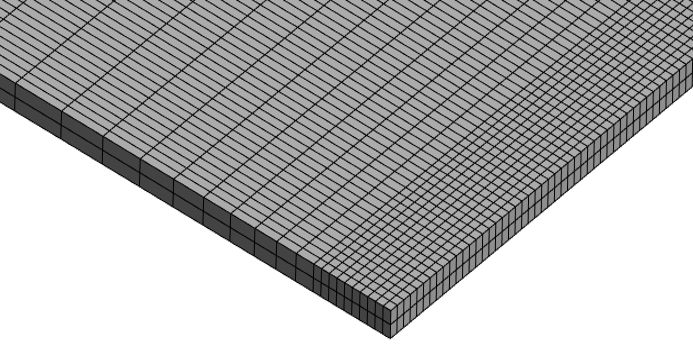

Finer mesh in the welding area for best results

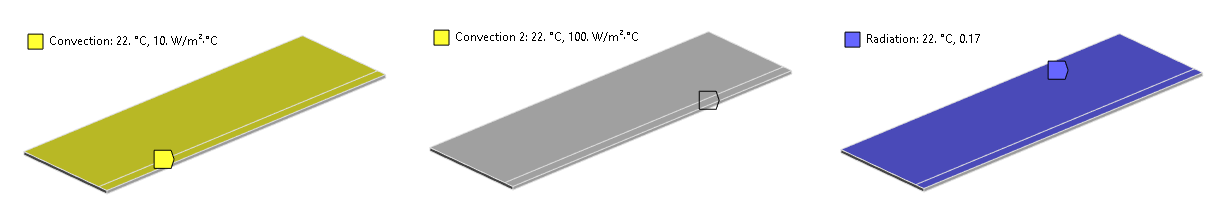

The convection coefficient is 10W/m2.C on the upper surface and 100W/m2.C on the lower surface, and a radiation coefficient of 0.17 is used in this analysis

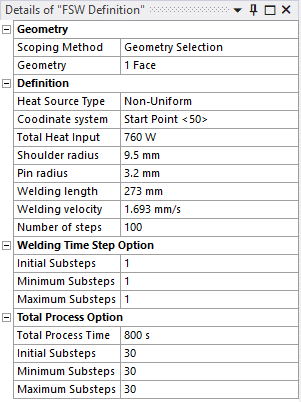

The pin tool has a shoulder diameter of 19.05 mm, and a pin diameter of 6.35 mm

The pin tool starts at 6.4 mm away from the edge, and stops after translation of 279.4 mm along the weld line. The tool translated with a velocity of 1.693 mm/s and the total welding time is 165s for each weld.

- Temperature result

Temperature at measure points (left – Simulation, right – Experiment)