Simulation of pipe bending process

Part 1: Material and Meshing

Part 2: Boundary conditions and Post-Processing

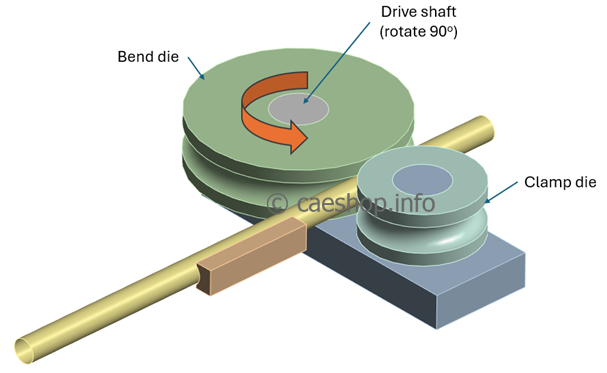

In this problem, thin tube model (Shell) is used with other details such as die, rotating shaft.

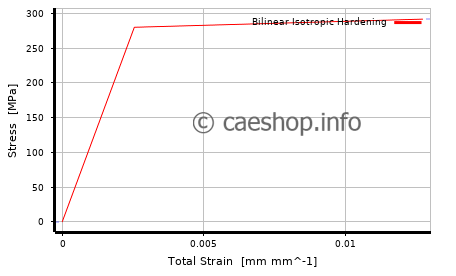

The tube is made of copper alloy with Bilinear Isotropic Hardening material model (yield point at 280MPa)

The dies will rotate around its axis and are defined through Joint (Body-Body). The contact between the bodies is friction with coefficient 0.2

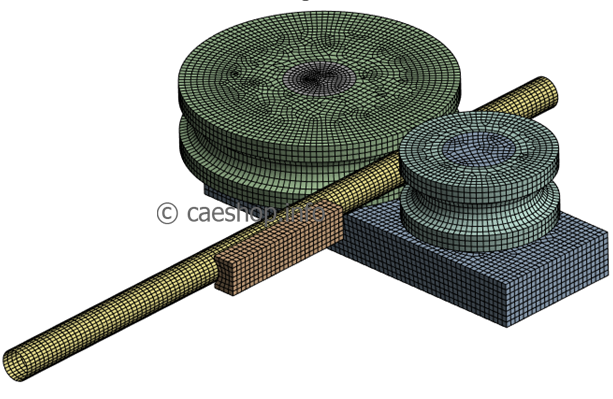

The mesh is concentrated for the tube and curved positions on the die to ensure the ability to identify the contact between the bodies

The analysis time is 0.1s. When using a fine mesh, the solution time increases significantly.

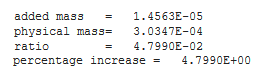

Mass Scaling is used to help solve the problem faster. However, you need to carefully check the added mass. You will see this information in the Solution Information:

The unit system being used is (tone, mm) so the added mass is 1.4563E-5 tone which is equivalent to 2.8% of the actual mass of the system. This value will not cause too much difference.

Some images of the results:

- Total Deformation

- Plastic Strain

- Equivalent Stress